New applications of nuclear energy help new development of scientific and technological innovation

Wastewater recycled from photovoltaic slices and lithium batteries is expected to solve the pain points of treatment through nuclear technology. Thermoplastic composite materials made in China are about to replace steel plate materials in automobiles to achieve significant weight loss. Chinese-made high-end medical equipment for proton therapy for tumors is accelerating research and development...·····The reporter learned from the Nuclear Technology Application Industry Chain Forum of the CGNPC Strategic Emerging Industry Development Conference held on March 20 that China's nuclear technology application industry is accelerating development. It is showing increasing potential in assisting the upgrading of traditional industries and the development of strategic emerging industries.

Nuclear technology can solve environmental pain points in multiple industries

At present, China's photovoltaic industry has entered a period of rapid development, with the installed capacity of photovoltaic power generation ranking first in the world. How to efficiently treat the slicing wastewater generated by photovoltaic companies during the production process has become one of the issues that needs to be paid attention to in the industry. In addition, with the rapid development of new energy vehicles, how to economically and efficiently treat wastewater from battery recycling is also worthy of attention.

Faced with the above two aspects, the reporter learned that the electron beam processing special waste technology "Hemei" jointly developed by China General Nuclear Power Group (hereinafter referred to as "CGNPC") and Tsinghua University has demonstrated unique advantages. Liu Peng, assistant general manager of CGNPC Dasheng Technology Co., Ltd., said that this technology uses instantaneous irradiation of a high-energy electron beam generated by an electron accelerator to directly destroy the molecular structure of pollutants. At the same time, the electron beam reacts with water molecules to generate highly oxidizing hydroxyl radicals, hydrogen radicals, etc., hydrogen peroxide and strongly reducing hydrated electrons, hydrogen radicals, etc., react quickly with pollutants to achieve decomposition, mineralization, disinfection and sterilization. This technology is characterized by high efficiency, low carbon, safety and reliability. It has been successfully applied in many fields such as printing and dyeing, and chemical industry, solving environmental pain points in many industries.

Wastewater treatment demonstration project of Shandong Heze Dongming Second Sewage Chemical Industry Park undertaken by CGNPC Dasheng Technology Co., Ltd., a subsidiary of CGNPC Technology

It is understood that CGNPC has conducted several rounds of pilot tests on photovoltaic slicing and battery recycling wastewater. The results show that after "Hemei" electron beam treatment, the removal rate of COD (Chemical Oxygen Demand) in photovoltaic slicing wastewater has stabilized at 55%. Above, it not only effectively improves the biodegradability of slicing wastewater pretreatment stage, but also solves the problem of treating high-concentration wastewater in the advanced treatment stage. In terms of battery recycling, test results show that COD and total phosphorus in wastewater can be effectively removed. The removal rate of the two indicators is stable at more than 98%, far below the emission standard, solving traditional technical problems.

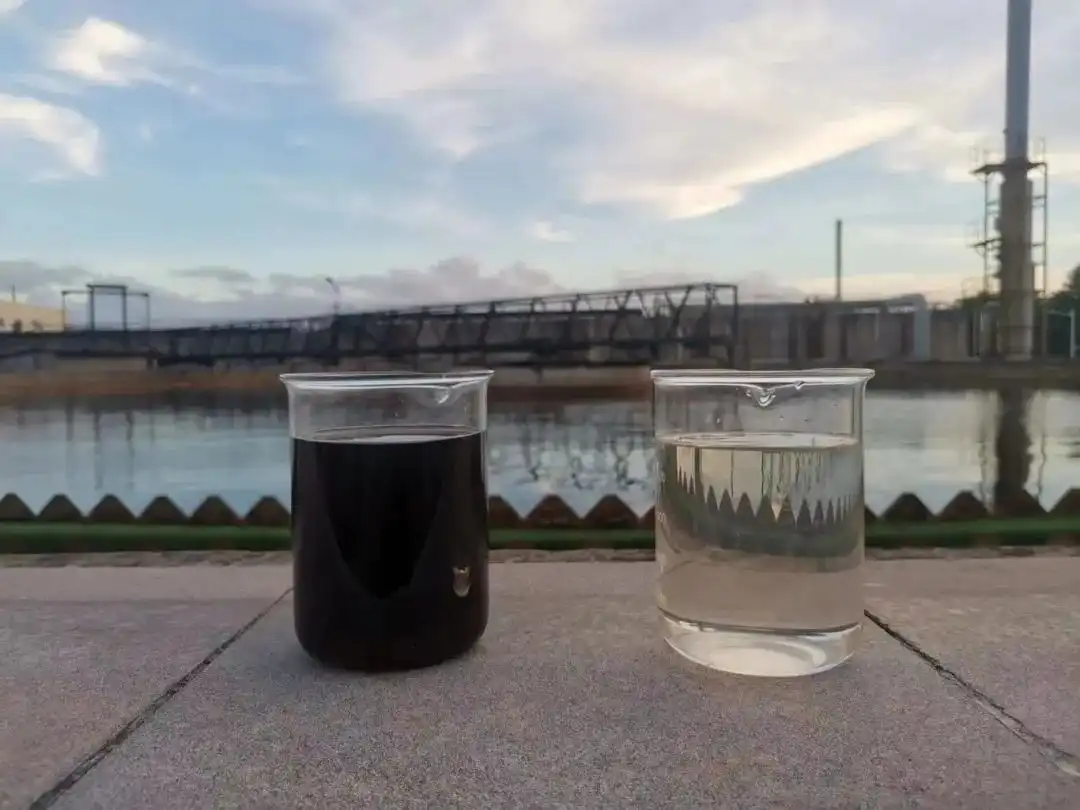

Comparison chart of industrial sewage after electron beam treatment from electron accelerator

It is reported that at this forum, CGNPC Dasheng Technology Co., Ltd. also signed a cooperation agreement on photovoltaic chip wastewater treatment with relevant companies, which will carry out wastewater treatment for the photovoltaic park of LONGi Green Energy, the world's largest photovoltaic company.

Completed the research and development of the first 100 kV DC PP insulation material in China during the year

Thermoplastic composites are currently one of the most advanced polymer materials in the world. China has successfully developed and begun to apply them in aerospace, automobiles, new energy, construction and other fields.

According to Song Yuxing, deputy director of the R & D Department of CGNPC Juner New Materials Co., Ltd., taking the automotive industry as an example, thermoplastic composite materials have been used in batches in battery pack covers. It replaces the originally used steel plate and replaces steel with plastic., plays a role in reducing weight and reducing weight, can improve the cruising range of new energy vehicles, and reduce corrosion caused by the use of steel plates. When the service of new energy vehicles ends, materials can be completely recycled and reused.

As one of the thermoplastic materials, the new polypropylene (PP) insulating material developed by CGNPC High-tech Nuclear Materials Group Co., Ltd. also appeared on the forum.

Data shows that compared with traditional cross-linked polyethylene, PP insulation material is recyclable and reusable. There is no cross-linking reaction and no scorch problem, which can improve the stability of cables. At the same time, there is no small molecule production during the production process, which reduces insulation gaps, and can effectively improve the service life of the cable and the insulation reliability of the cable.

At present, far-reaching offshore wind power and high-voltage and ultra-high voltage flexible submarine cables have become global hotspots.

Fei Churan, general manager of CGNPC High-tech Nuclear Materials Group Technology Co., Ltd., said that in this context, CGNPC will increase the research and development of PP insulation materials in the field of submarine cables and ultra-high voltage, and plans to complete the first 100 kV DC PP insulation materials in China in 2024. Research and development will be completed in 2025, and the first 525 kV DC (DC) PP insulation materials in China will be developed in 2026.

In addition to its applications in environmental protection and new materials, nuclear technology also has applications in fields such as medical care and security inspection. For example, in terms of nuclear security inspection, CGNPC Beigu Technology, entrusted and managed by CGNPC, focuses on independent innovation and overcomes key technical problems such as dual-energy material identification and three-dimensional image reconstruction. The self-developed security inspection CT system can not only efficiently and accurately identify packages. Prohibited items, but also realize the manufacturing of key parts and components in China. It is equipped with a self-developed centralized imaging review and intelligent mapping review system based on AI technology, and has been used in many scenarios such as Hainan Free Trade Port.

"Nuclear technology application is an important industry related to the national economy and people's livelihood and a typical representative of new productivity." Li Yong, Secretary of the Party Committee and Chairman of CGNPC Nuclear Technology Development Co., Ltd., said that he will give full play to the advantages of the embedded industry of nuclear technology application, accelerate scientific and technological innovation, deeply integrate with the industrial chain, actively promote the upgrading of traditional industries, and the growth and development of emerging industries. Accelerate the cultivation of new productive forces and make due contributions to the construction of a beautiful China, a safe China, and a healthy China.

author:Bai Yu

edit:Kong Kexing

proofreading:Tommy Cheung