Innovative breakthrough in thin liquid film boiling heat dissipation:Heat flow density exceeds 2000W/cm²

At present, in the fields of energy, power, electronic information and other fields, instruments and equipment continue to pursue miniaturization and integration, and the number of components per unit area continues to increase, putting forward higher requirements for heat dissipation. Xinhua Agency reported on March 17 that the Chinese scientific research team has made breakthroughs in the research of new heat dissipation mechanisms for equipment.

During the operation of mobile phones, computers, energy storage batteries and other devices and equipment, heating is inevitable. Achieving more efficient heat dissipation is an urgent problem that needs to be solved in many industries. The scientific research team of North China Electric Power University has successfully achieved an ultra-high heat flow density of more than 2000W/cm² in the research on a new heat dissipation mechanism-thin liquid film boiling, setting a new public record currently known at home and abroad, and is expected to further improve the heat dissipation of device equipment. effect. This result was recently published in the authoritative academic journal "International Journal of Heat and Mass Transfer".

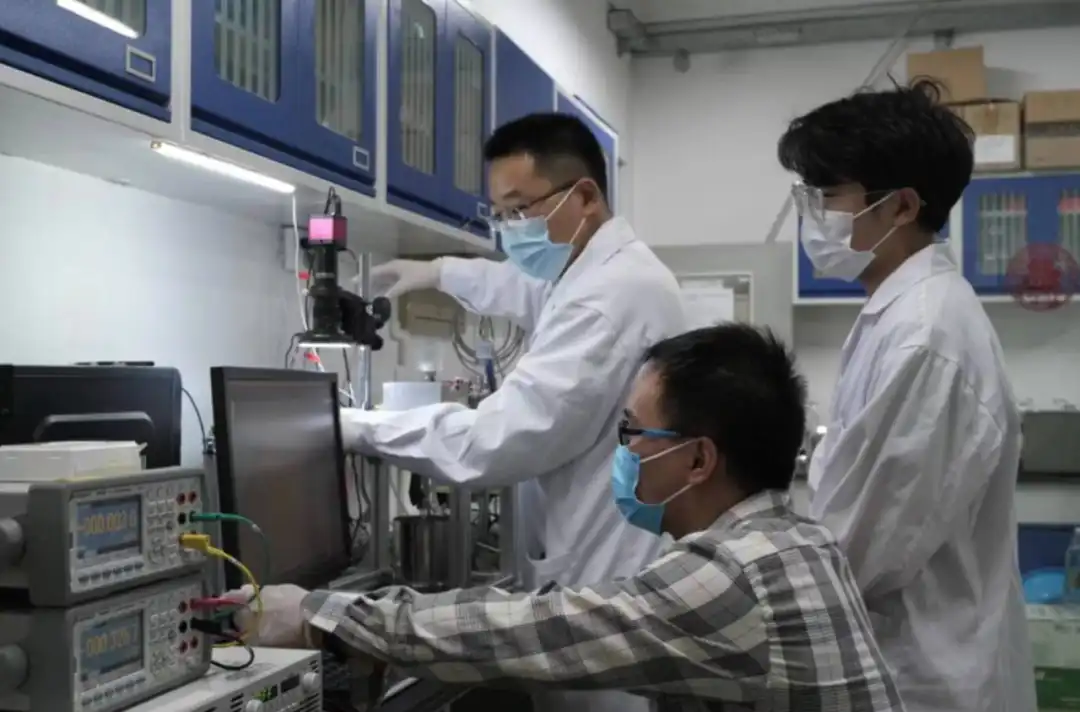

▲ The scientific research team of North China Electric Power University is debugging the thin liquid film boiling experimental system. (Photo provided by respondents)

At present, in the fields of energy, power, aerospace, electronic information and other fields, instruments and equipment continue to pursue miniaturization and integration, and the number of components per unit area continues to increase, which puts forward higher requirements for heat dissipation. Thin liquid film boiling is currently a cutting-edge method in the world that can achieve ultra-high heat flow density heat dissipation. It uses the ultra-thin liquid film formed by coolant on the surface of the heat source to continuously boil to achieve efficient heat dissipation.

"When some electronic equipment is running, the local heat output can reach more than 1000W/cm², which is significantly higher than the heat flow density of boiling water under normal pressure. Traditional air cooling, liquid cooling and other methods cannot meet the heat dissipation needs, which limits the equipment to a certain extent. Improvement in performance." Xian Haizhen, a professor at North China Electric Power University and a member of the team, said,"The heat flow density of 2000W/cm² achieved in the experiment is equivalent to 10,000 electric stoves with a power of 2 kilowatts simultaneously heating in an area of 1 square meter."

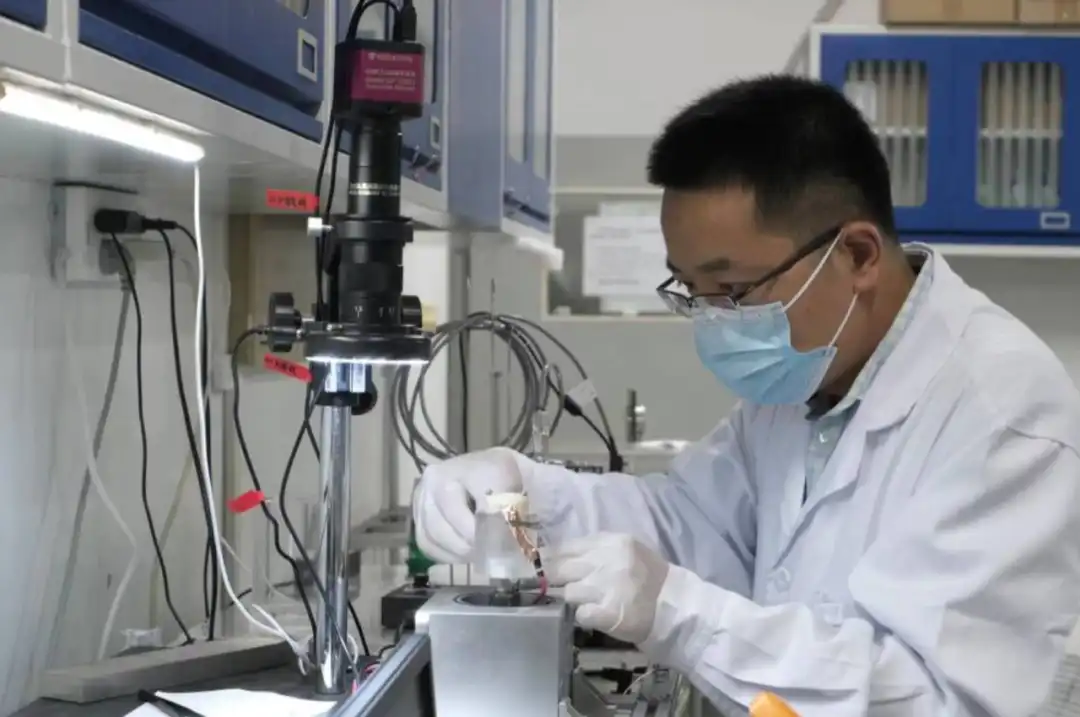

▲ Chen Lin, a professor at North China Electric Power University, is installing thin liquid film boiling experimental samples. (Photo provided by respondents)

Professor Du Xiaoze and Professor Chen Lin of North China Electric Power University are the other two members of the team. They introduced that before this experimental breakthrough was achieved, the heat flow density of internationally known thin liquid film boiling research could not exceed 1500W/cm². After years of research, the team found that under the constant pressure liquid supply mode, the experimental samples used to form thin liquid films are prone to rupture and fail. However, after changing to step pressurization and continuous pressurization, the critical heat flux density for thin liquid film boiling finally exceeded 2000W/cm². This successfully revealed that optimizing the liquid supply method can effectively improve the final performance of thin liquid film boiling.

"In other words, you should gradually increase the liquid supply pressure rather than maintaining the highest pressure at the beginning of operation." Chen Lin said that after the research results are transformed and applied, it is expected to better ensure the safety performance of electronic equipment, lithium batteries, etc.

A reviewer of the International Journal of Heat and Mass Transfer said that this achievement will advance the heat flow density of thin liquid film boiling to a new level and is of great significance for meeting extreme heat dissipation needs.