Quality Empowers Extraordinary, Technology Forges Monuments

project introduction

The Shougang Qian'gang Smart Dedusting Comprehensive Solution Project primarily involves two sets of dedusting systems, including the #Blast Furnace Ore Trough Dedusting System and the #Blast Furnace Taphole Iron Dedusting System. This project comprehensively optimizes or upgrades various aspects such as the fan unit (including high-efficiency energy-saving fans, inverters, and frequency conversion motors), electrical control systems, cooling systems, terminal valve systems, and pipeline networks. Under the technical requirements of experts from multiple fields of the client, after on-site surveys, tests, and several rounds of technical exchanges by relevant technicians from Ruichen Environmental Protection, a smart dedusting comprehensive energy-saving solution was finally provided. The solution promises a power saving rate and the real system energy consumption changes before and after the transformation as shown in the table below. The implementation of this project has achieved energy-saving effects that exceed expectations, meeting perfect delivery conditions.

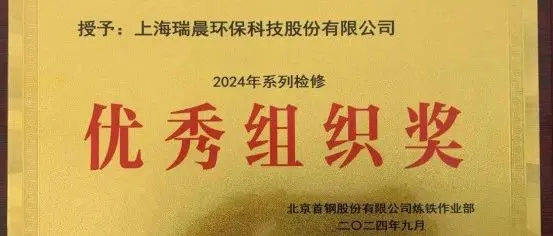

With the successful completion of the maintenance of the #blast furnace at Shougang Qian'an Iron and Steel, Shanghai Ruichen conducted acceptance work with Shougang's shares at the end of the year and month. During the acceptance meeting, the client expressed high praise for the transformation of the #blast furnace ore bunker and the furnace front iron removal dust removal system. The successful implementation and acceptance of this project transformation fully demonstrate Shanghai Ruichen's technical advantages in the dust removal field of the steel industry, and its forward-looking solution to the comprehensive problems of the dust removal system provides certain assistance for the energy saving, consumption reduction, and efficient production of steel mills.

Shanghai Ruichen Steel Industry Smart Dust Removal Comprehensive Energy-Saving Solution This solution is dedicated to reducing resistance and enhancing energy efficiency in the dust removal systems of steel enterprises through equipment upgrades, pipeline network optimization, high-efficiency and intelligent dust collector modifications, and intelligent system configuration control model upgrades, achieving a comprehensive power-saving rate of ≥%. Shanghai Ruichen has introduced expert system control models for secondary and tertiary steelmaking processes, ironmaking micro-dust control models, raw material transportation, and batching pipeline network balance control models, among others, tailored for various steel industry processes. These models control smoke emissions from workshops while optimizing air distribution, automatically optimizing and modeling pipeline networks, representing a comprehensive set of control models that enhance the efficiency, economy, safety, and intelligence of dust removal systems. Paired with Shanghai Ruichen's high-efficiency energy-saving fans, this approach aims to achieve dual energy savings in both process and equipment.

Shanghai Ruichen Environmental Protection Technology Co., Ltd. Efficient and energy-saving fan

- Centrifugal fan units achieve extreme energy efficiency, ensuring minimal energy consumption while safeguarding process production.

() Introduction of advanced foreign fan aerodynamic models and iterative design, backward single-plate design efficiency reaches .%, airfoil design efficiency reaches .%.

() Inlet is equipped with a low air leakage rate non-obstructive damper, minimizing valve losses during operation.

() Featuring a diaphragm coupling design, it ensures safety and stability while achieving a transmission efficiency of .%.

() Provide three-dimensional simulation, flow field analysis, optimize the inlet and outlet pipe networks of fans, and enhance the compatibility between pipes and fans.

- High adaptability of centrifugal fan design and operating conditions ensures high efficiency operation under multiple conditions.

() By integrating system design parameters with process operation characteristics, the multi-operating point design is employed to fully leverage the wide high-efficiency range of the fan.

After thorough technical communication with process design personnel, the fan design adopts a multi-operating point design, comprehensively calculating and selecting models based on the relevant parameters such as operating airflow, pressure, medium gas temperature, and medium gas composition at each operating point, ensuring that the fan's high-efficiency range covers all operating points.

Shanghai Ruichen Environmental Protection Technology Co., Ltd. Steel Industry Comprehensive Solutions

Industrial Circulating Water System - Comprehensive On-Demand Water Supply Solution, Power Saving Rate ≥%; Heating Furnace System - Comprehensive Heating Furnace Solution, Full Furnace Simulation, Extreme Waste Heat Recovery, Precision Combustion Control, Achieves Energy Saving %%; Emissions Less Than /(%); Billet Temperature Difference Characteristic Products - Dry Quenching Circulating Fan, Sintering Main Exhaust Fan, High Efficiency and Energy Saving, Domestic Alternative.