Jingang's zinc, aluminum and magnesium performance in resistance to salt fog was excellent in 3500 hours of testing

On March 27, Jingang's zinc, aluminum and magnesium received good news again, and the 3500-hour salt spray test performed well.

The zinc, aluminum and magnesium testing of Jingang is continuing to advance. As early as 17:00 on January 21, the zinc, aluminum and magnesium samples tested by Jingang for 2000 hours came out of the neutral salt spray test chamber:There is no red rust on the surface and passes the test. Nowadays, good news is spread again in 3500 hours, and from 2000 hours to 3500 hours in 65 days, day and night, which is inseparable from the hard work of the technical research and development team, and the redoubled efforts of high-end production lines and production personnel.

The group's cold products are based on the premise of meeting customer use. Salt spray tests simulate the experimental life of customer processed parts, and simulate the customer's actual use environment in the laboratory to truly achieve one suggestion in one place and lay a good foundation for guiding customer use. Jingang's technical R & D team tested zinc-aluminum-magnesium bends, incisions, and flat samples inside the salt spray test chamber according to actual use needs, and conducted follow-up testing for 3500 hours and performed excellent performance.

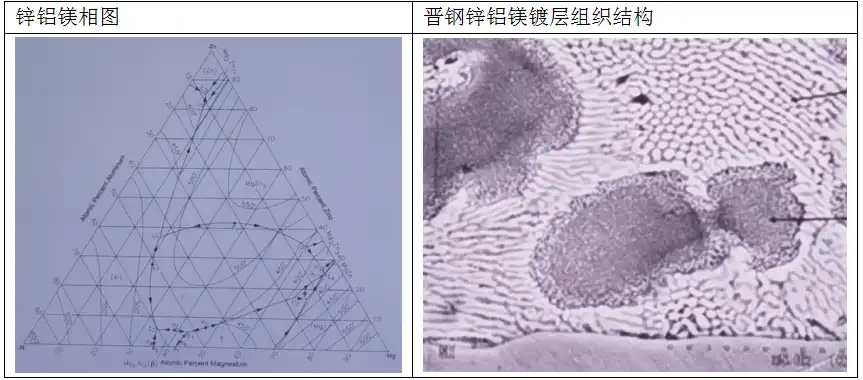

Jingang is confident that the salt spray test results of double-sided 275g/m² zinc-aluminum-magnesium products will win:It is inseparable from the high-end intelligent production line of Jingang Holding Group, the excellent production technical team of Jingang, and the real materials of Jingang's products. The group adheres to the concept of "quality builds the brand, integrity achieves the future", and the production of products adheres to the belief of real materials.:Ensure that the magnesium content is ≥2.5%, which greatly improves the service life of the product. The formation of ternary eutectics of zinc, aluminum and magnesium has reached the top level in China, which is inseparable from Jingang's precise control of coating composition and cooling rate, and truly grasps and skillfully applies the phase diagram of zinc, aluminum and magnesium.

The organizational structure of Jingang's zinc-aluminum-magnesium coating has been tested by authoritative scientific research institutions and is basically consistent with imported high-end 3magnesium 6aluminum zinc aluminum-magnesium products. This is a prerequisite for superior corrosion resistance of Jingang's products. This time, Jingang's zinc aluminum magnesium products once again lived up to expectations and withstood the 3500-hour salt spray test. The salt spray test of Jingang's zinc aluminum magnesium will continue to set new records.

author| Yuanbuchi

edit| Hao Shuhui

audit| Liu Jiajun

planning| Chen Xiaoli