Dedication and Lide R & D reaches a new level and obtains A-level recognition of R & D institutions of industrial enterprises in Hebei Province

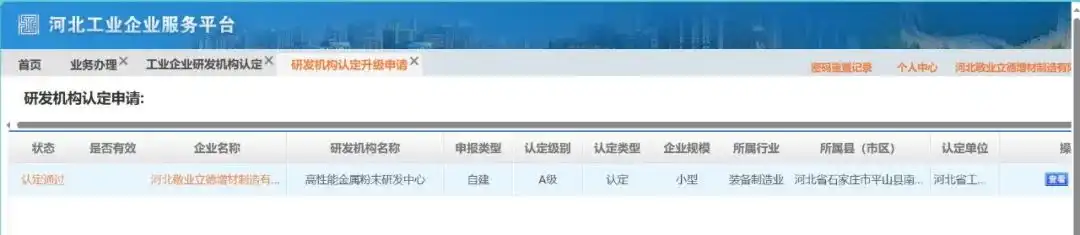

The "High-Performance Metal Powder R & D Center" of Hebei Jingye Lide Additive Manufacturing Co., Ltd. has been recognized by the R & D Institute of Industrial Enterprises in Hebei Province (Level A), marking that the R & D strength of Jingye Lide Additive has reached a new level.

It is reported that A-level institutions represent the highest level of R & D institutions of industrial enterprises in Hebei Province. The approval of the (A)-level certification of industrial enterprise R & D institutions in Hebei Province represents recognition of the overall scientific research level and ability of dedication and virtue, and also means that the company has made new breakthroughs in the level of innovation platform construction.

Under the guidance of the policy of "high technology leads the development of enterprises and promotes the use of high technology through variety development and technological reform", Jingye Lide Additives has continuously increased investment in R & D, and has made continuous efforts in core technology research and development, intellectual property protection, high-tech product mining, Provincial and municipal science and technology award application and other aspects, which has effectively promoted the improvement of the company's technological research capabilities. Today, Jingye Lide Additive has 10 valid patents, and another invention patent has been accepted. In 2023, Jingye Lide Additive will be awarded the title of Innovative Small and Medium-sized Enterprise in Hebei Province, and will be recognized as a National High-tech Enterprise in the same year.

Hebei Jingye Lide Additive Manufacturing Co., Ltd. has internationally advanced complete preparation technology for fine metal powder. Currently, it has 2 large-scale production workshops: water-gas combined atomization and injection molding, including 12 ultra-high pressure water-gas combined atomization production lines. It can produce 3000 tons of high-performance metal and alloy powders per year. The products are mainly used in aerospace, automotive and consumer electronics fields; There are 5 injection molding production lines, which can produce 127 tons of high-end parts and components in the fields of automobiles and consumer electronics every year. It connects with automobile and mobile phone customers such as Mercedes-Benz, Great Wall, Tesla, Apple, and Huawei. The company's product market share is more than 50%.

**