rock burst:The power of nature and countermeasures to prevent it

What is rock burst

Rock burst means井巷或工作面周围岩体,由于弹性变形能的瞬时释放而产生突然剧烈破坏的动力现象**,常伴有煤岩体抛出、巨响及气浪等现象。**

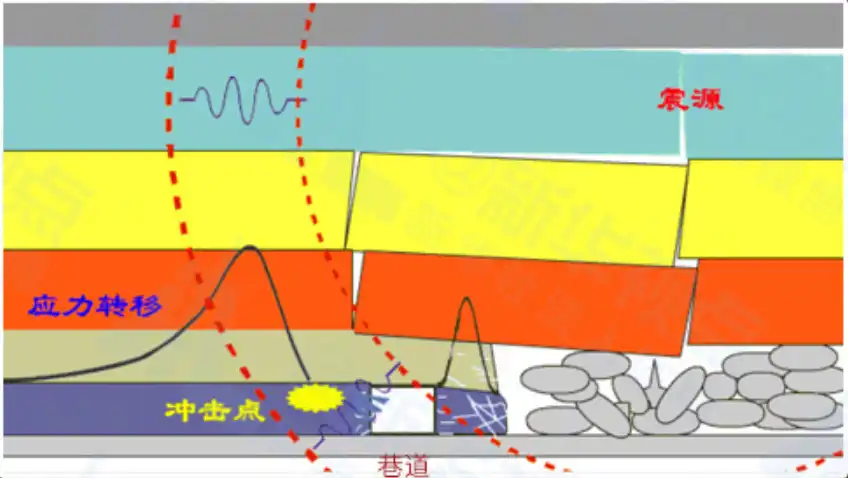

If the superimposed sum of the static load in the coal and rock mass and the dynamic load formed by the mine earthquake is greater than the minimum load inducing the impact of the coal and rock mass, an impact disaster will be induced.

main features

1. Sudden. There are generally no obvious precursors before the occurrence. A considerable number of rock bursts are caused by blasting, roof pressure, etc., but many of them occur during periods when there is no human activity. It is usually accompanied by strong vibration and sound, and sometimes the earthquake is still felt within a range of several kilometers on the ground. The impact process is short and lasts for a few seconds to tens of seconds.

2. It is generally manifested as coal explosion (coal wall bursting, small projectile). Shallow impact (occurs within the range of 2m to 6m of the coal wall and is highly destructive) and deep impact (occurs deep in the coal body, with sound like muffled thunder, and the degree of damage is different). The most common is coal seam impact, as well as roof impact and floor impact. Rock bursts occurred in a few mines. During coal seam impact, most of them are thrown out of coal, and a few are tens of square meters of coal moving as a whole, accompanied by loud sounds, rock vibration and shock waves.

3. Destructive. It often causes coal walls to fall, roof subsidence, floor heave, broken supports, blocked roadway, and casualties.

4. It is complex. In terms of natural geological conditions, the mining depth of all coal types except lignite ranges from 200m to 1000m, the geological structure ranges from simple to complex, the thickness of the coal seam ranges from thin to extremely thick, and the inclination angle ranges from horizontal to steep. The roof includes sandstone, limestone, kerogen shale, etc., and rock burst has occurred; In terms of technical conditions such as coal mining methods and coal mining processes, whether water mining, blasting mining, general mining or fully mechanized mining, the goaf treatment adopts the full collapse method or the hydraulic filling method. Rock burst has occurred in longwall, shortwall, room-pillar mining or column mining. However, longwall mining without coal pillars has fewer impact times.

What are the hazards?

1. Seriously damage the roadway, instantly shrink the roadway section, damage the support, and close the roadway in serious cases.

2. Damage to the equipment, causing the equipment to overturn, shift, damage and deform at the moment of impact.

3. Destroy the ventilation facilities. The powerful shock wave destroys the air doors and air ducts on the excavation face.

4. Casualties were caused, and most of the people were injured by impacts, shock waves, etc.

5. Rock burst in coal mines is not only harmful and has a wide impact, but is also the source of major accidents in other coal mines. When rock burst occurs, it may also induce abnormal gas gushing, coal and gas outburst, water burst, gas explosion and other disasters, causing more serious consequences.

how to prevent

Prevention measures for rock burst accidents mainly include:Comprehensive measures for impact risk prediction, detection and early warning, prevention and control, effect testing and safety protection.

Rock burst monitoring center

** **

**

Bolt-mesh O-shaped shed composite support

** **

**

Hydraulic support support for scour prevention tunnel

** **

**

Impact resistant clothing, impact resistant helmet

Basic requirements for the construction of demonstration mines for rock burst prevention and control in coal mines

1. General principles

Article 1 Demonstration mines for rock burst prevention and control shall meet the requirements of relevant regulations and standards for rock burst prevention and control such as the "Coal Mine Safety Regulations" and "Detailed Rules for the Prevention and Control of Rock burst in Coal Mines".

Article 2 These requirements apply to the construction of national coal mine rock burst prevention demonstration mines and related management work.

2. Sound management system

Article 3 Improve the working institutions for rock burst prevention and control. Establish a safety production management system for rock burst prevention with the main person in charge of the coal mine as the main person in charge, equip full-time deputy mine managers or deputy chief engineers for rock burst prevention, and establish independent rock burst disaster prevention and control departments and professional construction teams.

There shall be no less than 10 full-time staff in the rock burst prevention department of mines with severe rock burst, and no less than 6 people in other rock burst mines; among them, no less than 50% shall be technical personnel, and the technical personnel shall have at least a junior college degree.

The professional construction team for rock burst disaster prevention and control shall be equipped with full-time team leaders and technical personnel, and the number of personnel shall meet the needs of mine rock burst prevention work.

Article 4 Establish and improve a rock burst prevention and control management system that conforms to the actual situation of the mine in accordance with regulations, regularly carry out rock burst risk assessment and hidden danger investigation, establish management systems such as risk assessment, plan design and implementation, project quality control, and hidden danger investigation, and clarify The main responsibilities of the design (improvement), implementation (execution), inspection (acceptance) and organization (coordination) of rock burst prevention and control plans, and strictly assess and implement them. Establish and improve the rock burst prevention technical management system with the chief engineer as the main part. Strictly implement the safety technical management system for rock burst prevention, the comprehensive technical analysis system for rock burst risk, the safety investment guarantee system for rock burst prevention, the acceptance system for rock burst projects, etc.; carry out monthly investigation of potential rock burst hazards, and hold rock burst prevention meetings every day to analyze the early warning of rock burst risks and the inspection of control effects. Measures should be taken in a timely manner when there are signs of rock burst. If there is a dynamic phenomenon of rock burst, the causes should be analyzed in a timely manner and the rock burst prevention measures should be revised and improved in a timely manner.

Establish and improve the implementation system of on-site rock burst prevention measures mainly based on deputy mine managers or deputy chief engineers. Strictly implement staff restriction management in dangerous areas, quality management of rock burst prevention projects, and safety protection measures, reasonably arrange labor organization and operation construction in accordance with rock burst prevention requirements, and effectively implement early warning and disposal instructions.

Article 5 Establish and improve the rock burst prevention training system. In accordance with the rock burst prevention training plan, all staff training, professional technical personnel and management personnel training shall be carried out; special training for key personnel shall be carried out at least once every quarter based on the actual situation of rock burst prevention.

Article 6 Establish an incentive mechanism for rock burst prevention. Merit personnel who have made great contributions to rock burst prevention and control and achieved remarkable results shall be rewarded; rock burst prevention personnel who have achieved remarkable results in promoting new technologies and new equipment shall be rewarded.

3. Optimization of mining deployment

Article 7 Adhere to the principles of "regional first, local follow-up, zoning management, and classified prevention and control", and in accordance with the requirements of "one mine, one policy" and "one policy for one side", in response to key factors such as large mining depths, thick hard roofs, and geological structures, adopt regional comprehensive rock burst prevention measures to prevent rock burst from the source.

The advancement speed of the coal mining face and the production capacity of the mine should be determined in accordance with the requirements of mine rock burst prevention, so as to ensure that the layout and continuation of mine mining are reasonable, and to resolutely put an end to tension in the continuation of mining.

Article 8 Adopt regional preventive measures such as reasonable development methods, mining layout, mining sequence, coal pillar reservation, coal mining methods, coal mining techniques and mining protective layers.

Mine design, mining area design and mining face design should give priority to meeting regional rock burst prevention requirements, avoid stress concentration in roadways and coal mining faces, and reduce the impact of structural stress. Development roadways shall not be arranged in coal seams with severe rock burst, and mining shall be carried out in strict order, and isolated coal pillars shall not be left. Priority is given to small coal pillar, no coal pillar or negative coal pillar mining methods.

If there are conditions for mining protective layers, protective layers must be mined.

Rock burst mines shall predict and optimize the design of the regional preventive measures (rock burst risk) in the design of the mining area (panel) and the design of the mining face.

4. Supporting rock burst prevention equipment

Article 9 Set up a special rock burst monitoring and early warning duty room, equipped with a comprehensive rock burst early warning platform, integrate the monitoring (inspection) data of each monitoring system, and realize intelligent voice early warning.

Corresponding monitoring and prevention equipment should be equipped according to the impact risk level. For areas with no and weak impact risks, monitoring equipment mainly including microseismic monitoring, stress monitoring and drilling debris monitoring are mainly equipped. For areas with moderate and above impact risks, in addition to complete monitoring equipment, pressure relief and danger relief equipment should also be equipped.

Article 10 Provide low-frequency microseismic monitoring systems and use microseismic monitoring systems to monitor high-energy and low-frequency events above 1Hz. The monitoring scope of the microseismic monitoring system must cover all mining areas and adjacent goaf areas of the mine.

Article 11 A ground sound monitoring system shall be equipped to monitor the dynamic pressure affected areas of the coal tunnel driving face with the risk of rock burst, and monitor the rupture information of surrounding rock, mainly ground sound events of 30 to 2000Hz.

Article 12 A coal stress monitoring system shall be equipped to conduct real-time stress monitoring on coal mining faces, tunneling faces and main coal pillar areas with risks of rock burst. Focus on monitoring coal seam roadways such as intake and return wind troughs within 300 meters in front of the mining face and the roadways within 200 meters behind the heading face.

Article 13 Mining working faces with a risk of rock burst shall be subjected to CT detection, and rock burst risk analysis shall be carried out in key areas or important periods such as square mining faces.

Article 14 Equipped with a working resistance monitoring system for hydraulic supports in coal mining faces to monitor online the working resistance of working faces supports; equipped with a real-time online monitoring system for roof separation of coal lanes and semi-coal and rock lanes supported by bolting and shotcreting. Layer separation monitoring.

Article 15 Provide a sufficient number of drilling cuttings method detection machines to detect the mining stress affected areas of the coal mining face road, the head-on and rear dynamic pressure affected areas of the coal tunnel driving face, etc.

Article 16 Provide sufficient number of pressure relief drilling rigs, including at least one drilling rig with a torque of not less than 800N·m.

At least one preventive pressure relief rig shall be equipped with each gate of coal mining faces with the risk of rock burst, and at least one preventive pressure relief rig shall be equipped with each all-coal and semi-coal-rock excavation face.

At least one drilling rig that can remotely control coal seam drilling to relieve danger and pressure.

Article 17 According to the needs of disaster control measures, hydraulic fracturing or blasting equipment for roof breaking and bottom breaking construction shall be equipped.

Equipped with a precise personnel positioning system to strictly monitor the number of workers hitting dangerous areas.

Video surveillance should be installed at the upper and lower exits of the heading face and coal mining face in areas with moderate and above impact risk, or at advanced support roadways and coal seam drilling construction sites.

Article 18 At least one scientific research institution, colleges and universities, etc. jointly carry out scientific and technological research on rock burst prevention and control with mines, focusing on the mechanism of rock burst, the types and characteristics of rock burst, and targeted rock burst prevention measures. Actively promote and apply the latest monitoring technology, carry out early warning of impact risks and prevent and control disasters.

5. Effective monitoring and early warning

Article 19 Build a rock burst monitoring and early warning system (platform) for full-time, full-frequency, full-area, and full-factor. The display and control terminals of the monitoring and early warning system (platform) shall be set up in the mine dispatching room, or the rock burst monitoring room shall be set up. Direct access and strong plug in the dispatching room telephone.

Conduct a comprehensive analysis of the risk of rock burst every day on monitoring data, production conditions, etc., determine the risk level of rock burst, and compile a daily monitoring and early warning report, and report it to the deputy general manager of coal mine rock burst prevention or deputy mine manager, chief engineer, and mine manager for rock burst prevention. Approval, and timely inform relevant units (departments) and personnel.

Sensors for monitoring systems such as microearthquakes, ground sounds, and online stress should be installed and constructed by professionals in accordance with the monitoring network layout plan designed by the mine.

Stress CT detection should be carried out on site under the guidance of the rock burst prevention department in accordance with the detection plan.

Article 20 Based on the rock burst risk monitoring data and actual conditions, determine the risk early warning indicators and check them in a timely manner to improve the accuracy of early warning.

Clarify the release, disposal procedures and disposal results feedback process of early warning information. The personnel on duty shall record the early warning time, early warning scope, measures taken and disposal situation in detail, and form a summary report.

Article 21 A comprehensive evaluation of the operation and use of the microseismic monitoring system shall be carried out at least once a year, and the monitoring plan shall be adjusted in a timely manner according to changes in the mining layout of the mine.

Regularly inspect, maintain and check rock burst risk monitoring equipment to ensure the normal operation, accuracy and effectiveness of the rock burst risk monitoring system.

Article 22 Improve rock burst prevention data and ledgers, properly keep various monitoring data and reports, and promptly fill in maps for the layout of rock burst prevention projects and monitoring equipment to effectively guide production safety.

System (platform) data must be able to be stored and queried, backed up regularly, and kept for no less than two years.

6. Reliable local measures

Article 23 Mining working faces shall, on the basis of implementing regional preventive measures, promptly follow up effective coal seam pressure relief and local scour prevention measures such as breaking roof and bottom. For rock burst risk areas where hard roofs and geological structures are the main disaster-causing factors, effective prevention and control measures and projects for the main disaster-causing factors should be formulated and implemented.

Article 24 After implementing hazard relief measures at rock burst dangerous working faces, the effect test must be carried out. The sand cutting method, stress monitoring method or microseismic monitoring method can be used to test the impact of rock burst prevention. There must be no less than two inspection methods, and the inspection scope and frequency shall be approved by the chief engineer of the coal mine. Confirm that the inspection results are less than the critical value, and mining operations can be carried out only after it is determined that there is no danger after research and judgment.

Article 25 Mines with high gas, coal and gas outburst, mining coal seam prone to spontaneous combustion, and complex hydrogeological types with high gas pressure risk, shall comprehensively consider and formulate comprehensive technical measures to prevent and control rock burst and abnormal gas emissions based on the conditions of the mine., coal and gas outburst, coal seam spontaneous combustion, and water damage.

VII. Construction safety

Article 26 Longwall comprehensive mechanized intelligent mining shall be adopted for rock burst coal seams, and long-distance power supply and liquid supply shall be used to achieve no (few) people in the mining area; long-distance control shall be adopted for the drilling construction of coal lanes in areas with rock burst danger.

Article 27 For coal mining faces with a risk of rock burst, the length of advance support of the roadway shall be determined according to the influence range of advance support pressure of the coal mining face, comply with relevant regulations and requirements, and shall be approved by the chief engineer of the coal mining enterprise.

For coal mining faces with moderate or above rock burst risk, hydraulic supports should be used for advanced support of upper and lower exits and roadway.

Article 28 For excavation tunnels with a risk of rock burst, the support design parameters shall be selected with a safety factor above medium.

For driving roadways with moderate and above rock burst risk, highly prestressed full-length bolt-grouting cables, yielding anchors, high-strength surface protection steel strips, high-strength protective nets, large-diameter trays, etc. should be used. Active support methods with strong deformation resistance and surface protection capabilities, and in conjunction with the use of retractable U-shaped steel sheds, hydraulic unit supports or portal supports and other enhanced support methods that still have a safe space after impact. The support method and scope shall be approved by the chief engineer of the coal mining enterprise.

Article 29 Strictly implement the system of restricting people in rock burst dangerous areas, and implement intelligent management such as closed management, overloading alarm, and automatic stop of working machines and tools.

Article 30 Establish a production organization notice system. Every month, the rock burst prevention department shall set the maximum daily footage and shift footage of the tunnel and coal mining face based on the design of the mining face, combined with on-site production conditions and the results of rock burst risk monitoring and judgment. When conditions change or monitoring indicators are abnormal, a production organization notice will be issued in a timely manner to adjust the production organization and report it to the main person in charge of the coal mine for approval.

Article 31 When it is found that the monitoring data exceeds the critical indicator for rock burst risk warning, personnel unrelated to the rock burst prevention operation shall be evacuated and the work of relieving the danger and relieving the pressure; when it is determined that there is a rock burst risk, personnel in the threatened area shall be evacuated immediately, and cut off the power supply and implement the rock burst prevention plan.

Please watch, like, and share the triple combo so that more people can see it!

::