smart mine:Share support, pay attention to encouragement, and assist transformation and upgrading

01 Background

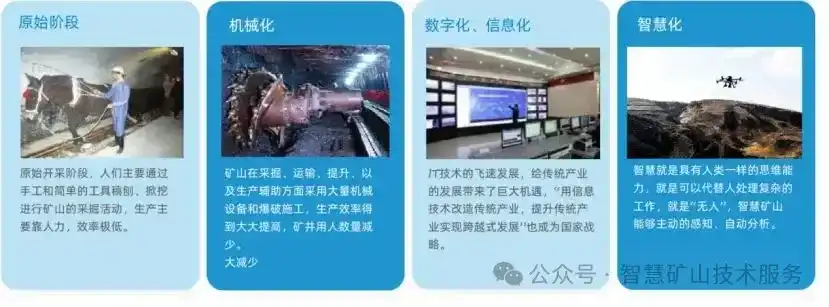

With the rapid development of information technology and the increasingly urgent needs for mine management, smart mines have emerged as an innovative mine management method. Smart mines rely on advanced information technology to achieve intelligence, efficiency, and synergy in all aspects such as mine production, management, and safety, which is an inevitable trend in the transformation and upgrading of the mining industry.

02 Pain points

In traditional mine management, there are many pain points, which seriously restrict the development of the mining industry. First, the isolation of information and data makes it difficult to integrate information resources and systems, and data cannot be deeply utilized. Secondly, disaster monitoring methods are passive and lack initiative and predictability, making it difficult to effectively respond to mine safety risks. Thirdly, each control system is in a local and limited control state and lacks a unified coordination and joint control mechanism. Finally, mine management relies too much on empirical judgment and lacks reliable sharing and intelligent analysis of data information.

03 Program

In response to the above pain points, we propose the following overall solutions for smart mines:

#3.1. Establish a unified information management platform

In the mining field, with the continuous development of science and technology, the accumulation of various information systems and data resources in mines has become increasingly abundant. However, for a long time, these information systems and data resources have often fought independently, forming information islands, resulting in waste of resources, inefficiency, and may even cause security risks. Therefore, integrating various information systems and data resources in mines, breaking down information islands, and realizing the sharing and in-depth utilization of information resources have become urgent problems in the current mining field.

In order to integrate all kinds of mine information systems and data resources, it is necessary to comprehensively sort out and analyze the existing mine information systems. This includes production management system, safety monitoring system, geological exploration system, equipment management system and other aspects. Through an in-depth understanding of the functions and characteristics of these systems, we can find out the similarities and differences between them, and lay the foundation for the follow-up integration work. In the process of integration, we need to use advanced technical means, such as big data, cloud computing, Internet of things, etc., to achieve data exchange and information sharing among various systems. By building a unified data platform, the data of each system are gathered together to form a complete data resource pool. In this way, mine managers can grasp the information of mine production, safety and equipment in real time through this platform to provide support for decision-making. To realize the sharing and deep utilization of information resources, it is necessary to establish a set of perfect information management and analysis system. This includes all aspects of data cleaning, sorting, storage, analysis and mining. Through the in-depth mining and analysis of the data, we can find the potential problems in the mine production process, and put forward improvement measures to improve the production efficiency. At the same time, through the real-time monitoring and analysis of safety data, the hidden dangers of safety can be found in time and effective measures can be taken to ensure the safety of mine production.

In addition, integrating various information systems and data resources in mines also requires strengthening personnel training and management. Mine managers need to cultivate a team of talents with information technology and mining knowledge to ensure that they are proficient in the use of various information systems and data resources. At the same time, it is also necessary to establish a sound information security management system to ensure the security and integrity of data.

3.2. Introduce active disaster monitoring technology

In the field of mine safety, the introduction of advanced sensor technology and big data analysis technology is crucial to achieving real-time monitoring and early warning of mine safety risks. The combined application of these technologies can not only significantly improve the initiative and predictability of disaster prevention, but also bring a safer and more efficient working environment to mine production.

The application of sensor technology makes the acquisition of mine safety monitoring data more accurate and timely. By deploying various sensors in key areas of the mine, such as temperature sensors, pressure sensors, displacement sensors, etc., various safety indicators inside the mine, such as temperature, pressure, displacement, etc., can be monitored in real time. These sensors can accurately capture subtle changes in the internal environment of the mine and provide a rich data source for subsequent data analysis and early warning.

The application of big data analysis technology has further improved the accuracy and timeliness of mine safety risk warning. By deeply mining and analyzing a large amount of data collected by sensors, potential laws and abnormal changes in the data can be discovered, thereby predicting the probability and trend of mine safety risks. This big data-based early warning method can not only detect potential safety hazards in a timely manner, but also provide scientific decision support for mine production.

The establishment of real-time monitoring and early warning systems also needs to consider the actual needs of mine safety management. For example, real-time monitoring data can be combined with the mine safety management system, and hierarchical management of mine safety risks can be achieved by setting different safety thresholds and early warning levels. In this way, once the monitoring data exceeds the set safety threshold, the system will automatically trigger an early warning mechanism to remind mine managers to take timely measures to intervene and deal with it.

3.3. Build an intelligent coordination and joint control system

With the continuous advancement of technology, artificial intelligence and Internet of Things technology have become the key to the transformation and upgrading of many industries. In the field of mine production, by introducing these two technologies, we can realize intelligent coordination and joint control of various control systems, further improving mine production and management efficiency.

First, let us discuss the application of artificial intelligence in mine production. Traditional mine production often relies on manual monitoring and operation of various control systems, which is not only inefficient, but also prone to human error. By introducing artificial intelligence technology, we can build an intelligent monitoring system to realize automated monitoring and regulation of the entire process of mine production. These intelligent systems can independently optimize production parameters by learning historical data and operating rules, predict potential risks, and automatically adjust the control system when necessary to ensure the stability and safety of the production process.

Internet of Things technology also plays an important role in mine production. Internet of Things technology enables real-time transmission and sharing of data by connecting various sensors and devices to the Internet. In mine production, by installing sensors on key equipment and systems, we can obtain various data during the production process in real time, such as temperature, pressure, flow, etc. These data can be centrally managed and analyzed through the Internet of Things platform to provide decision support for production managers. At the same time, Internet of Things technology can also realize remote control and fault diagnosis, reduce the need for on-site personnel intervention, and improve production efficiency.

Through the combined application of artificial intelligence and Internet of Things technology, we can build an intelligent mine production management system. This system can realize intelligent coordination and joint control of various control systems and improve mine production and management efficiency. Specifically, this system can collect and analyze production data in real time, predict production trends and potential risks, and automatically adjust the control system to adapt to production needs. At the same time, the system can also realize functions such as remote control, fault diagnosis and early warning to improve the safety and stability of mine production. In addition, the introduction of artificial intelligence and Internet of Things technology can also bring other benefits. For example, through data analysis and prediction, we can optimize production planning and resource allocation, reducing waste and costs. At the same time, these technologies can also improve employee work efficiency and work quality, and reduce the risk of human error and accidents.

3.4. Promote intelligent analysis and decision-making systems

With the rapid development of science and technology, advanced technologies such as big data and machine learning have penetrated into various industry fields, bringing unprecedented changes to production and management. Especially in the mining industry, the application of these technologies has become an important means to improve production efficiency, ensure safety, and optimize management.

In the mine production process, there are many types of data involved, including geological exploration data, production progress data, equipment operation data, etc. Traditional mine management models often rely on empirical judgment. However, this method has great limitations and it is difficult to conduct comprehensive and in-depth analysis of massive data. By introducing big data and machine learning technology, intelligent analysis of these data can be achieved, thereby providing more scientific and accurate support for decision-making.

The application of big data technology enables mining companies to collect, store and process massive amounts of data. By building a big data platform, mining companies can integrate various types of data to form a comprehensive and complete data set. These data include not only real-time data during the mine production process, but also historical data, external data, etc. Through comprehensive analysis of these data, mining companies can have a deeper understanding of various laws and trends in the production process and provide more comprehensive and accurate information support for decision-making.

The application of machine learning technology can further improve the intelligent level of data analysis. By training machine learning models, mining companies can automatically classify, predict and optimize data. For example, by training historical production data, machine learning models can predict future production trends, thereby providing a more scientific basis for the formulation of production plans. In addition, the machine learning model can also conduct real-time monitoring and early warning of equipment operation data, discover potential safety hazards in a timely manner, and ensure the safety and stability of mine production. In addition to playing an important role in the production process, big data and machine learning technologies can also provide strong support for the management of mining companies. Through data analysis on employee performance, cost control and other aspects, mining companies can more accurately understand the operating conditions of the company and provide a more scientific and reasonable basis for management decisions. At the same time, these technologies can also help companies optimize human resource allocation, improve production efficiency, reduce operating costs, etc., thereby achieving sustainable development.

Using technologies such as big data and machine learning to intelligently analyze mine production and management data has important practical significance and application value. Through comprehensive and in-depth analysis of data, these technologies can help mining companies make decisions more scientifically and accurately, optimize management, improve production efficiency, and ensure safety and stability. With the continuous advancement of technology and the continuous expansion of application scope, it is believed that these technologies will play a more important role in the mining industry in the future.

04 Value

The implementation of the overall smart mine solution will bring significant value to the mining industry. First, by improving the production efficiency of mining equipment and optimizing equipment maintenance and management, production costs are reduced and economic benefits are improved. Secondly, by improving the safety of mine work, we can reduce the occurrence of safety accidents and ensure the safety of employees. Finally, by reducing staff and increasing efficiency, intelligently improving quality and efficiency, we will enhance the comprehensive competitiveness of enterprises and promote the transformation, upgrading and sustainable development of the mining industry.

Please watch, like, and share the triple combo so that more people can see it!

::