China's Glasses Capital:The rise of Danyang Mirror Industry from scratch

There are many magical small cities in China. 70% of the world's disposable lighters come from Shaodong, Hunan, 75% of the country's lenses come from Danyang, Jiangsu, 50% of the country's baby carriages come from Pingxiang, Hebei, and 60% of the world's ties come from Shengzhou, Zhejiang... In these small cities, tens of thousands of people or even hundreds of thousands of people are engaged in the same industry. Although the industry is small, it is a well-deserved "treasure industry" in terms of employment-driving capabilities and industrial layout, and it is also a valuable asset in China's manufacturing system. The Economic Daily will launch "Visiting the Treasure Town" from now on, to walk into the small town and get a glimpse of the industries that we are both familiar and unfamiliar.

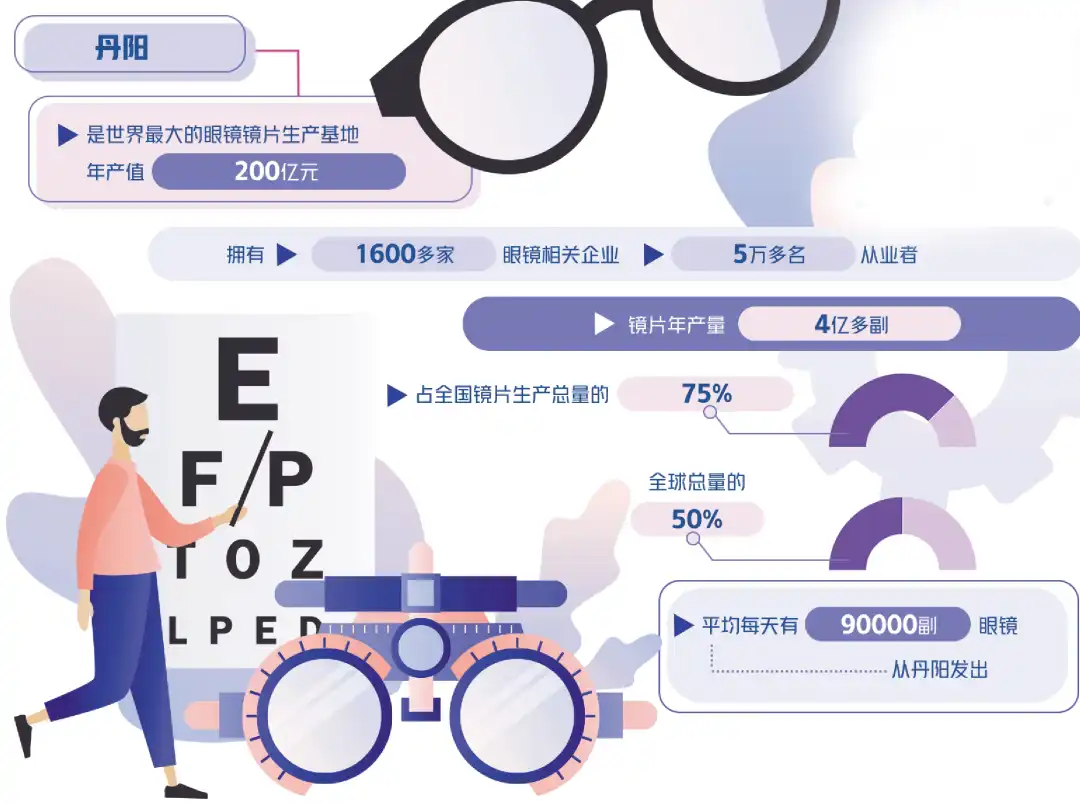

In Danyang, Zhenjiang, Jiangsu Province, when it comes to the optical industry, many local people know everything from home:There are more than 1600 opports-related companies and more than 50,000 practitioners in the area. The annual output of lenses is more than 400 million pairs, accounting for 75% of the country's total lens production and 50% of the global total. It is known as the "China's Eyeglasses Capital".

眼镜这一特色产业是如何在丹阳从无到有、发展壮大的?面向未来,产业发展中存在哪些问题?近日,记者走进丹阳一探究竟。  From Shack Factory to Glasses Capital

From Shack Factory to Glasses Capital

Looking south from the high-speed railway Danyang Station, the two huge signboards of China Danyang Optical City and China Danyang International Optical City are very eye-catching. Outside the glasses city, there is a lot of traffic, and the glasses city is crowded with people. Buyers and consumers with accents from all over the world choose products here.

"This lively scene has been going on for decades." Hu Xiaosuo, 77, is one of the founders of Danyang Optical Market. He told reporters that in the 1960s, a group of opticians from Shanghai and Suzhou jumped in line to Danyang. Under their technical guidance, Danyang began to get involved with glasses.

江苏丹阳眼镜城。 经济日报记者蒋波摄

江苏丹阳眼镜城。 经济日报记者蒋波摄

"At that time, glasses production was mainly scattered in small workshops, with simple equipment, production relying entirely on hands, and quality relying entirely on the experience and feeling of the workers and masters. Therefore, it was also called the 'Shopeng Glasses Factory'." Hu Xiaosuo said that against the background of shortage of goods and strong demand in the market, small workshops in shacks quickly ignited the spark of the development of Danyang's glasses industry. Collective enterprises and township enterprises with eyeglass lenses as their main products have mushroomed in Danyang.

Founded in 1973, Wanxin Optical Group Co., Ltd. was formerly known as Danyang Situ Lens Factory, a township enterprise. Ouyang Xiaoyong, vice president of the company, said that Danyang is located in the middle of Shanghai, Jiangsu and Zhejiang. Relying on developed railway, canal water transport, and road transportation conditions, Wanxin glasses were quickly sold to all parts of the country.

Peng Xianghua, owner of Danyang's white-collar aristocratic optical shop, was one of the earliest local merchants engaged in optical sales. Her first bucket of gold was earned by setting up a stall in front of Danyang Railway Station. "I accidentally took a train and discovered a business opportunity to set up a stall to sell glasses. Then I went to the team office glasses factory and received 100 pairs of glasses frames. I earned more than 20 yuan in half a day, which is equivalent to several times the monthly salary at that time." Peng Xianghua said that the huge demand for glasses made her decide to set up her own factory and start customized production of glasses.

In order to support the development of the glasses industry, in 1986, Danyang selected two villages, the station and Shuangmiao near the railway station, to build the country's earliest "Huayang Glasses Market" and "Yunyang Glasses Market" dedicated to glasses trading.

"Today, Danyang has formed an industrial chain integrating design, research and development, and production, with all parts such as lenses, frames, mirror boxes and even nose pads." Hu Xiaosuo said that whether it is hardware facilities or supporting services, Danyang Optical City has strong competitiveness in the Chinese and even the world optical market due to its large-scale, technological and professional attitude.

"Around the world, one pair of glasses worn by every two people comes from Danyang." Wu Dongwei, a member of the Party Leadership Group of Danyang City Economic Development Bureau, told reporters that after decades of development and integration, the Danyang glasses industry has formed a complete industrial chain with complete materials and accessories, complete production, sales and logistics, detailed division of labor, a certain scale of supporting facilities, and smooth upstream and downstream connections.

The industry supports the market, and the market promotes industrial development. Danyang has become the world's largest lens production base and Asia's largest distribution center for optical products. It has also promoted the integrated development of secondary and tertiary industries such as local "optical-matching tours".

Technology support helps products go out to sea

Technology support helps products go out to sea

Walking into Wanxin Optics 'lens production workshop, 3 automated production lines and 11 sets of rough grinding equipment are arranged in turn, and pieces of resin lens blanks move slowly on the conveyor belt, neatly and uniformly. Accompanied by splashing water and the sound of machine operation, after a series of processes such as feeding, grinding, and polishing, 5 minutes later, a blank resin lens transformed into a customized lens.

"After years of exploration and practice, Wanxin Optics took the lead in developing CR-39 resin lenses in the industry and gradually replaced glass lenses, driving the company's sales to increase significantly." Ouyang Xiaoyong said that the successful research and development of resin lenses has played a strong role in promoting the development of the local glasses industry.

At the beginning of the rise of resin lenses, raw material technology was mainly in the hands of foreign companies such as South Korea and Japan. In order to overcome the technical difficulties of raw materials and master the manufacturing technology of high-refractive-index resin lenses, local glasses companies in Danyang began to tackle difficulties. Wang Xueping, vice president of Mingyue Lens, told reporters that in order to realize the manufacturing of raw material production in China, Mingyue Lens has jointly tackled key problems with Nanjing University of Technology and chemical companies. In 2007, it achieved technological breakthroughs and independently developed the 1.71 series, PMC Ultra-Bright, KR Ultra-Toughness, KR Resin and other lens materials, breaking the monopoly of foreign investment and achieving mass production of materials. At the same time, the price of raw materials from nearly 300,000 yuan per ton has been reduced to less than 50,000 yuan per ton.

Wanxin Optics and Mingyue Lenses are a microcosm of the development and growth of Danyang's glasses industry. Technological research has given Danyang's glasses companies the confidence to compete with foreign companies. However, the aroma of wine is also afraid of deep alleys. How to sell its products is also a question Danyang has been thinking about.

Walking into the Danyang Optical E-commerce Industrial Park, this 3600-square-meter building has dedicated live broadcast rooms, office areas, public training classrooms, etc. to provide services for enterprises to carry out e-commerce.

江苏汇鼎光学眼镜有限公司智能化镜片生产车间。(资料图片)

江苏汇鼎光学眼镜有限公司智能化镜片生产车间。(资料图片)

"This is a presbyopic mirror we launched specifically for the elderly this year. It is clearer, lighter, more durable, and very comfortable to wear. If you need it, you can place an order directly." In the live broadcast room of Jiangsu Huiding Optical Glasses Co., Ltd., staff are selling glasses products through e-commerce platforms. Lan Huafeng, director of the e-commerce department of Jiangsu Huiding Optical Glasses Co., Ltd., told reporters that Huiding Optical was established in 2017. Through the e-commerce platform, sales have increased exponentially in just a few years.

Zhang Yan, head of Danyang Optical E-commerce Industrial Park, told reporters that currently, there are 16 companies settled in the park, including foreign trade sales companies, comprehensive service companies, and e-commerce training companies. In 2023, the sales of e-commerce platforms of enterprises stationed in the industrial park will reach 155 million yuan, with more than 3600 live broadcasts throughout the year.

In recent years, Danyang optical companies have also actively explored cross-border e-commerce export development models. Jiangsu Taojing Co., Ltd. is a company focusing on overseas markets. "Relying on cross-border e-commerce platforms, Taojing has achieved global independent sales of personalized glasses. For the whole year of 2023, sales will exceed 650 million yuan." Hu Hongmei, deputy general manager of Jiangsu Taojing Co., Ltd., said that by providing diversified and personalized customized services to overseas users, their company has successfully established a foothold in the North American market.

“为帮助企业更好开展跨境电商业务,我们与超过20家跨境电商平台开展了合作。”张琰告诉记者,2023年,丹阳眼镜电商产业园为入驻企业开展包括知识产权保护、跨境电商运营在内的30多场业务培训,为企业“出海”发展提供指导。  Industrial progress still needs to cross several levels

Industrial progress still needs to cross several levels

How is a thin lens produced? The reporter saw in the Mingyue lens production workshop that more than 10 processes were needed from the selection of raw materials for eyeglass substrates to raw material filling and curing, to lens hardening and coating strengthening.

"Most of the core design technologies and raw materials of high-end products are controlled by foreign companies, which has compressed the profits of domestic lens manufacturers to a certain extent. Without core technology, key materials are controlled by others, and the entire glasses industry will be controlled by others." Wang Xueping said that with other parameters being the same, the higher the refractive index of the lens, the thinner and clearer the lens will be, and the higher the selection and technical requirements of resin materials will be. At present, domestic high-end substrate raw materials, coating raw materials, and high-end equipment and optical technology still mainly rely on imports. If the development of the glasses industry wants to make a breakthrough, the first thing that needs to be overcome is the technical level of raw materials and equipment.

In addition, cost pressure is also a problem facing current optical companies. "Each user's eye condition is different, so the specifications of each lens cannot be exactly the same. The production of resin lenses requires a lot of manual operations to ensure stable product quality." Ouyang Xiaoyong said that the optical industry is a labor-intensive industry with complex production processes. There is still a long way to go to become an unmanned "light-off factory." In recent years, corporate profits have continued to decrease, labor costs have continued to increase, and the pressure to promote the transformation of intelligent and automated production methods has also increased.

Establishing an independent brand is another important hurdle that needs to be crossed for the high-quality development of Danyang's glasses industry. According to relevant data from the Danyang City Economic Development Bureau, except for a few well-known enterprises with large scale and high output value, most optical companies in Danyang are mainly engaged in OEM production and OEM services, with low market awareness. Industry experts said that if Danyang's glasses industry wants to achieve high-quality development, it must further increase investment in scientific and technological research and development, accelerate breakthroughs in a number of core technologies and key common technologies such as lens, parts and raw material production technologies, and promote industry technological upgrading.

Promoting the glasses industry to increase varieties, improve quality and create brands has become an urgent need for the transformation and upgrading of Danyang's glasses industry. Wang Chengming, Secretary of the Danyang Municipal Party Committee, said that Danyang will actively guide and give full play to the advantages of the glasses industry, promptly enter the new track of the virtual reality industry, improve the supply capacity of high-end products, and continuously enhance the core competitiveness of Danyang glasses.